Hardwearing and durable feature solid timber batten system with acoustic backing options for walls and ceilings.

Featurecraft has options for responsibly sourced materials - ask for our certified products.

The colours shown are as accurate as possible, but we recommend that you request product samples before making a final selection.

All timber species have their own natural variations of colour and grain and product samples may not fully reflect the colour variation that can occur.

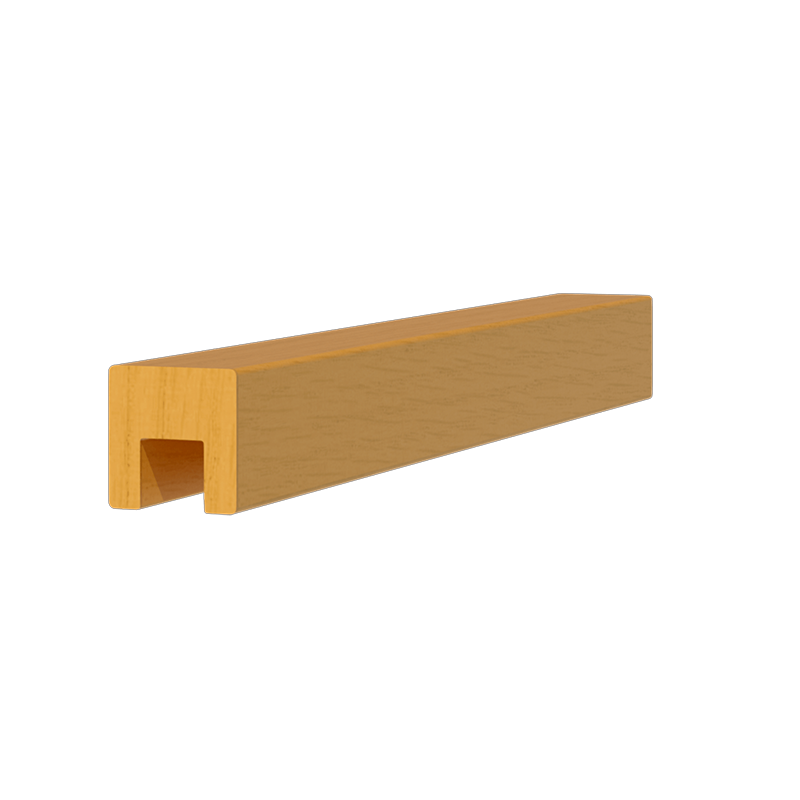

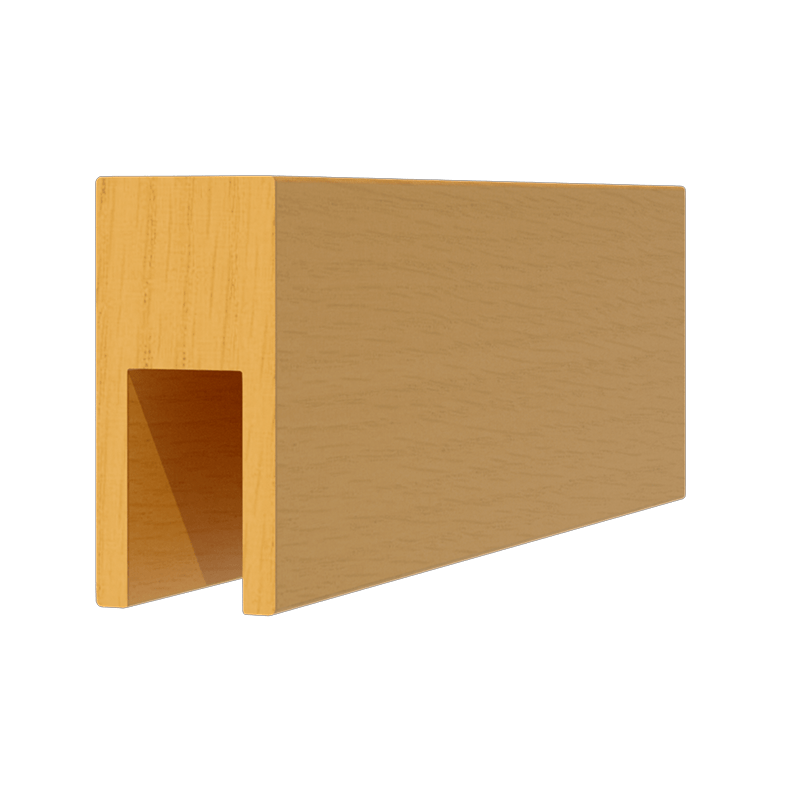

Solid Timber species above:

ask for our FSC® & PEFC™ certified timbers

All battens are finished in the factory. Featurecraft clear flat varnish is our standard finish

Some white wash & stains are available if matching to other finishers is required. Please contact us today.

Acoustic backing panels can be 12mm (0.40 NRC) or 25mm (0.60 NRC) and are incorporated into the system for great NRC performance. They also reduce costs as they can replace the need for alternative wall & ceiling lining.

The acoustic panels have a Group 1 (Aus) and Group 1S (NZ) fire rating and are available in the range of colours shown.

Alternatively, acoustic blanket is recommended for achieving up to 0.95 NRC

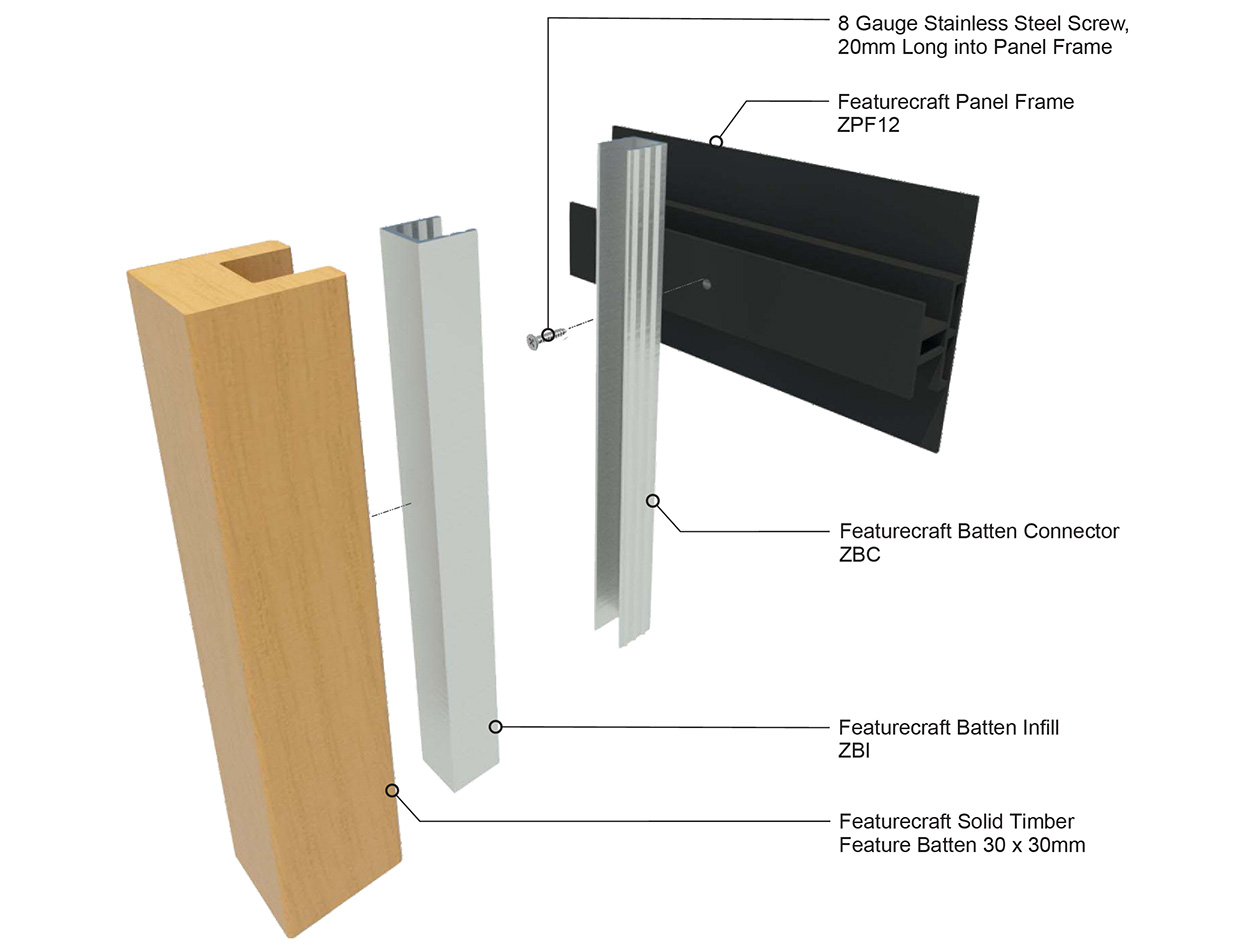

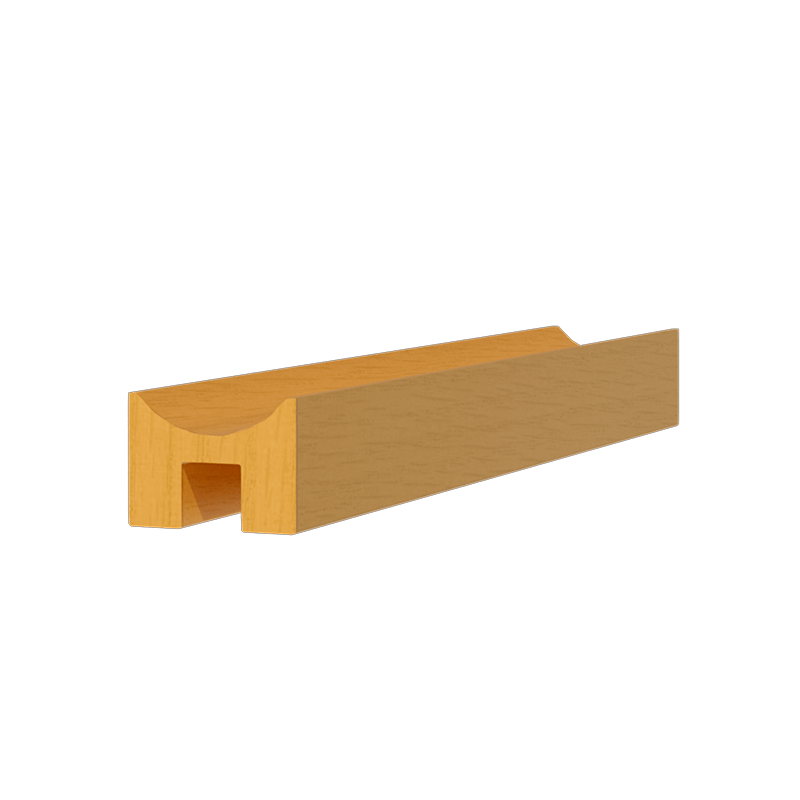

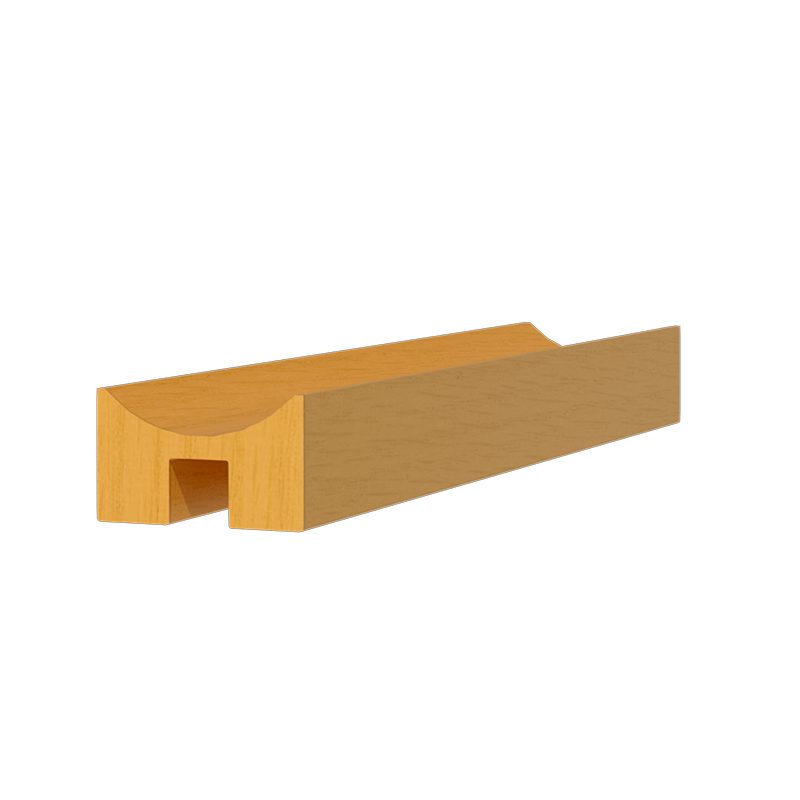

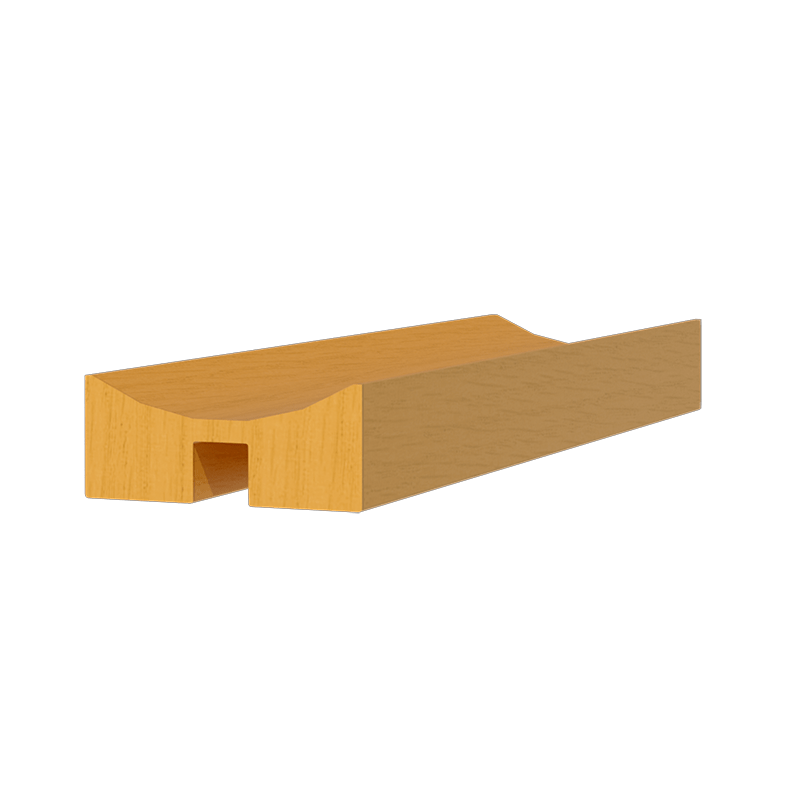

The male and female aluminium track is screw fixed into the back of the batten and the front of the horizontal track.

The Featurecraft panel frame is horizontally screw fixed onto timber or steel framing at 450mm to 600mm centres then the 12mm acoustic backing is slid into place between the panel frames. The Featurecraft batten connector is then screw fixed onto the panel frame at the desired spacing and the Featurecraft batten infill is screw fixed into the back of the rebated feature batten and simply clicked into place. A very quick and simple installation.

Click here to view PDF version of the section views showing the ZPF panel frames' dimensions.

The curve-able Featurecraft panel frame is horizontally screw fixed onto timber or steel framing at 450mm to 600mm centres then the 12mm acoustic backing is slid into place between the panel frames. The Featurecraft batten connector is then screw fixed onto the panel frame at the desired spacing and the Featurecraft batten infill is screw fixed into the back of the rebated feature batten and simply clicked into place. A very quick and simple installation.

The Rondo components are Flexible Track 103 (51mm), 107 (64mm), 108 (76mm) and 109 (92mm) and steel studs to suit.

The Featurecraft batten connector is screw fixed through the existing lining into timber or steel studs at the desired spacing and the Featurecraft batten infill is screw fixed into the back of the rebated feature batten and simply clicked into place. A very quick and simple installation.

The Featurecraft panel frame is horizontally screw fixed onto timber or steel framing at 450mm to 600mm centers. The 12mm acoustic backing is slid into place between the panel frames.

The Featurecraft batten connector is then screw fixed onto the panel frame at the desired spacing and the Featurecraft batten infill is screw fixed into the back of the rebated feature batten and simply clicked into place.

A very quick and simple installation.

The Featurecraft batten connector is screw fixed onto the Gib or framing at the desired spacing, followed by the Featurecraft batten infill screw fixed into the back of the rebated feature batten. Then the batten - infill first - is simply clicked into place onto the batten connector

A very quick and simple installation.

The curve-able Featurecraft batten frame is horizontally fixed onto the Rondo Keylock joiner 139, then the 12mm acoustic backing is slid into place between the batten frames. The Featurecraft batten connector is then screw fixed onto the batten frame at the desired spacing followed by the Featurecraft batten infill screw fixed into the back of the rebated feature batten. The batten is simply clicked into place. A very quick and simple installation.

The Rondo components are Flexible Track 103 (51mm), 107 (64mm), 108 (76mm) and 109 (92mm) and steel studs to suit.